NACO Louvre System

NACO Aluminium Louvre System

For more than forty years, NACO has been the world’s leading manufacturer of glass, aluminium, wood and PVC oriented sheet shutters. NACO has achieved great success both in Italy and abroad with different types of products, all characterized by excellent raw materials, functional technical solutions, elegant design and original ideas.

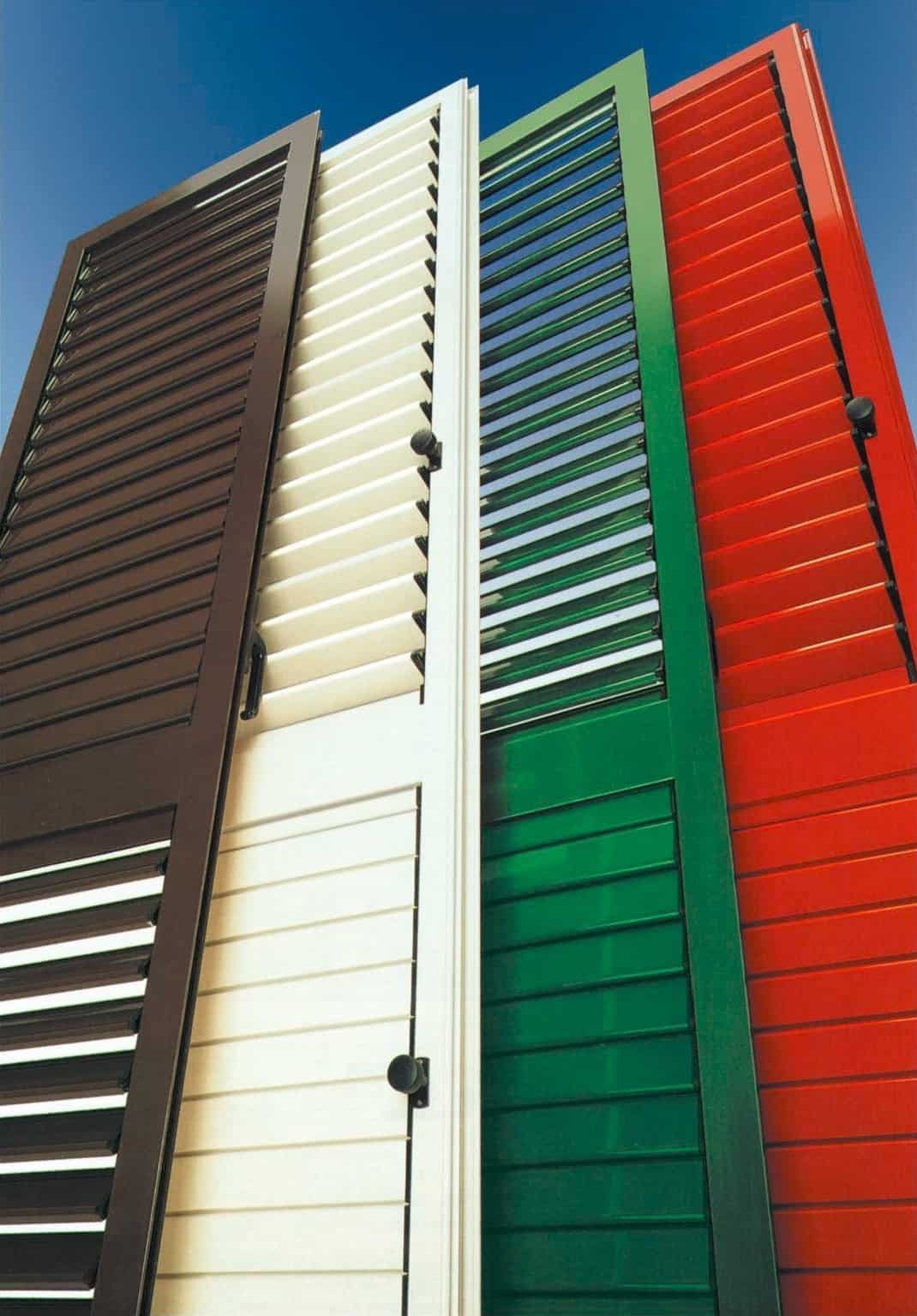

The aluminium louvre system, with solid and well-finished aluminium louvre blades, achieves high performance and maximum functionality for air control, perfectly defends your house from noise, sun, rain and dust.

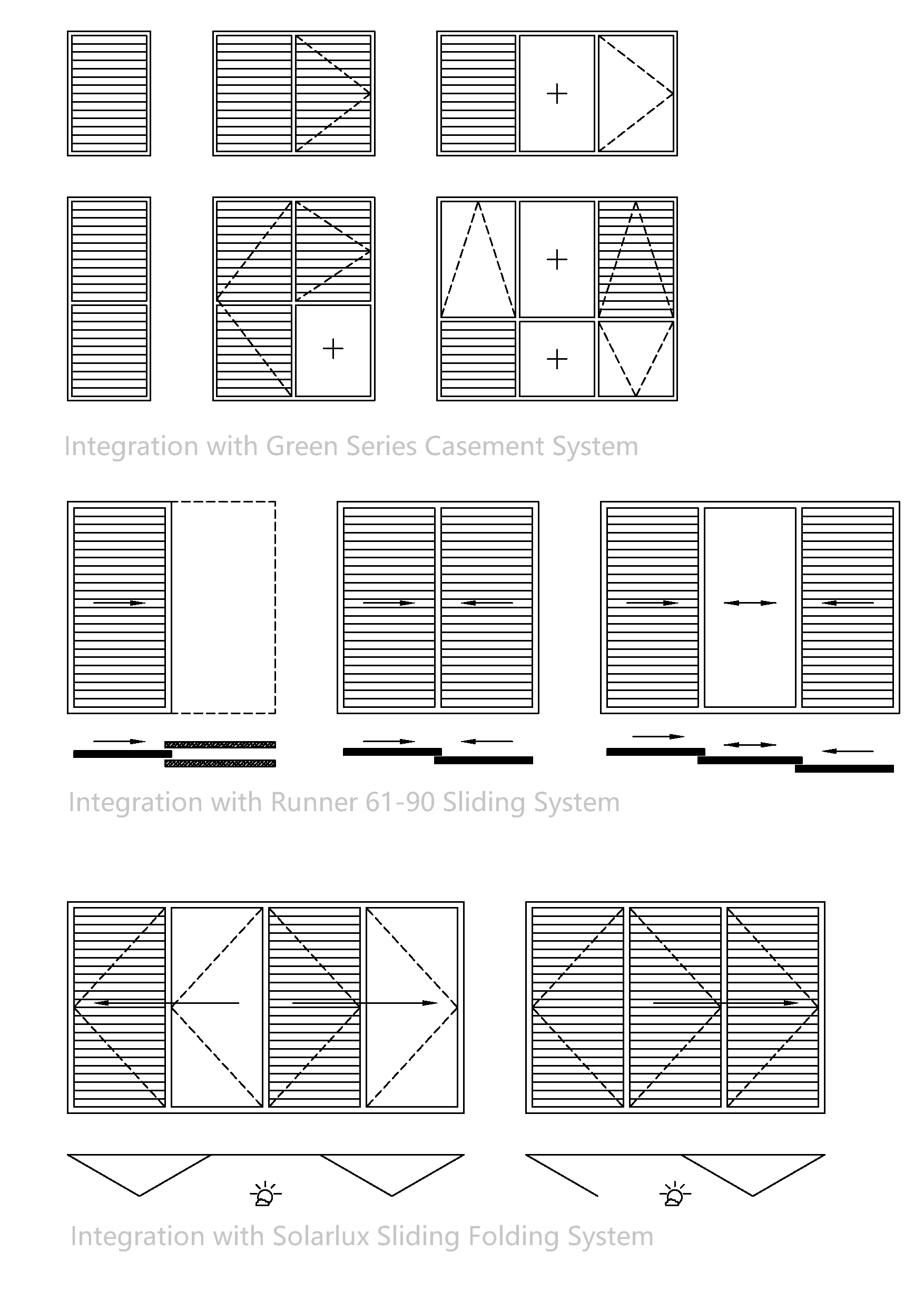

The NACO aluminium louvre system can be installed within a wide range of window frames, such as Green Series casement system, Runner 61-90 sliding system, or Solarlux sliding folding system for residential and commercial applications.

TECHNICAL DATA

Characteristics

Profile system

Max. width per unit

Max. louvre opening angle

Louvre spacing

Locking options

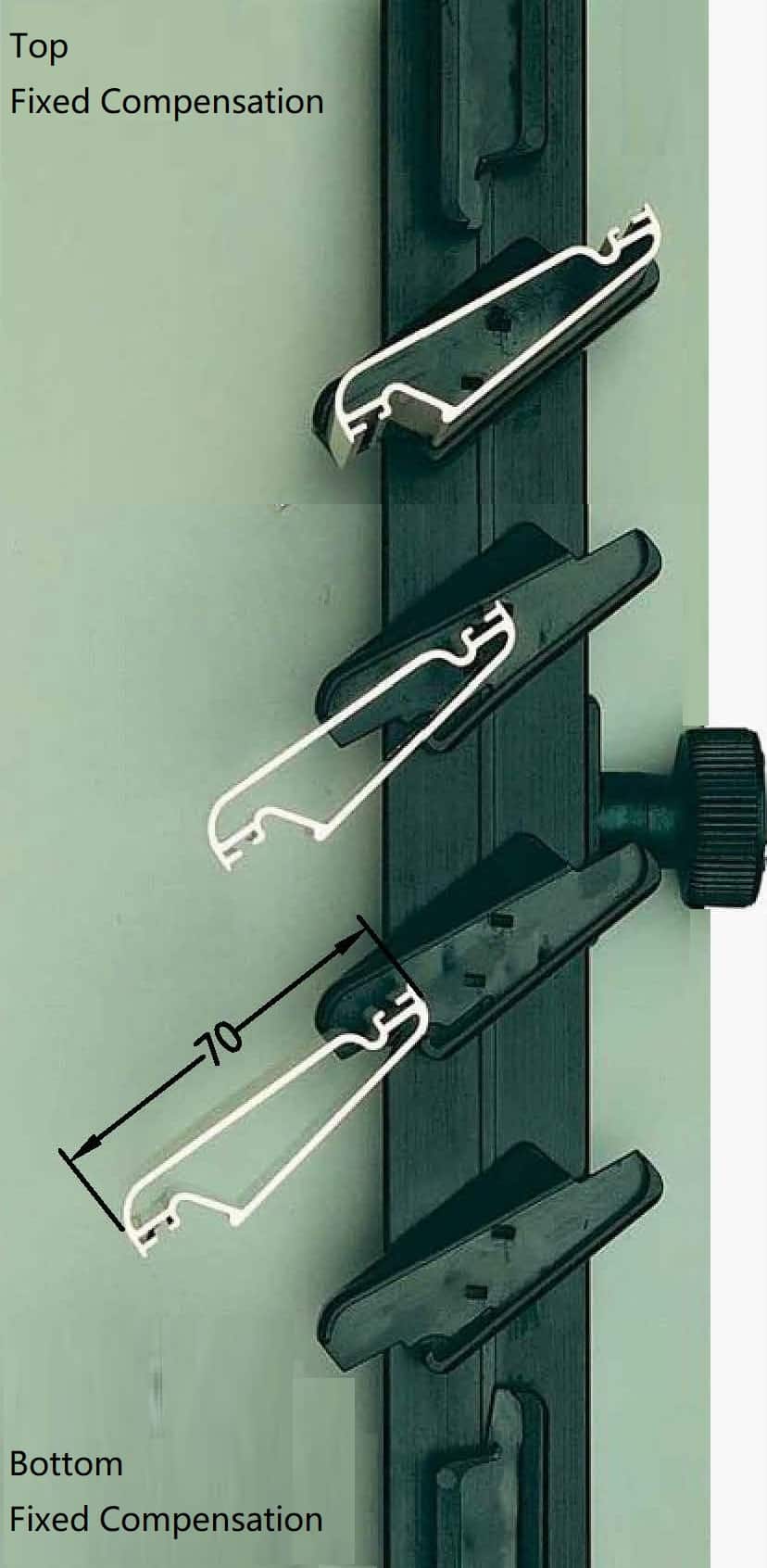

PE.R.LA.70 Aluminium Louvre

70mm aluminium louvre blade

up to 1.0 m, larger on request

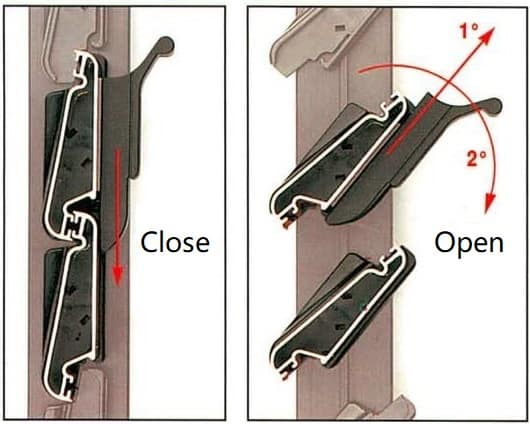

up to 80o

60mm

Operator handles: standard ROTARY handle, INOX handle, SL handle

FEATURES

Maximum functionality for air control

The PE.R.LA. 70 window offers aesthetic, quality and reliable products for daily ventilation.

- More than thirty years’ experiences

- Ease of operation

- Elegant aluminium blades coated to frame colour

- Durable operating mechanism requires no maintenance

- Integration with mosquito screen

- Compatibility with various window systems

Compensation at top & bottom.

- Necessary for a perfect closure

- Ease of operation

Standard ROTARY handle

It is equipped with a safety stop, allowing the blades locked both in the closure and in various intermediate positions.

SL handle

- Made with stabilized material

- Resistant to temperatures from to

- Can be positioned on any blade, right or left hand side

- Ideal for integration with sliding system

INOX handle

- Durable handle made of stainless steel in black paint

- Can be pre-assembly to the operating mechanism

New ROTARY handle

- New aesthetic design

- Comfortably operation

- Robustness to drive up to 50 blades

APPLICATIONS