Solarlux cero

Solarlux cero

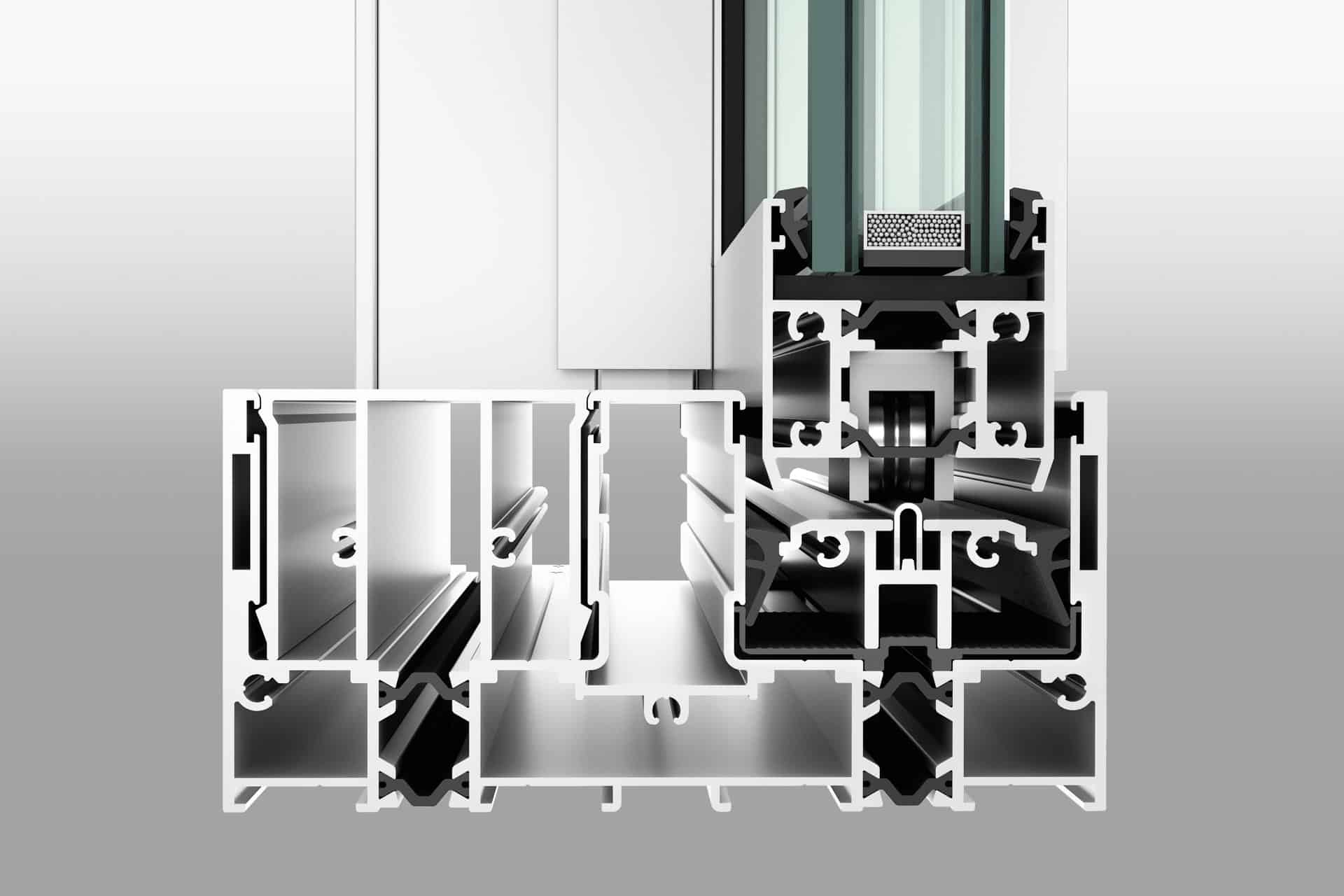

Large-scale fixed or moveable cero elements combine architecture, design and technology in a masterful way. At only 34 millimeters wide, the slim aluminium profile enables maximum transparency. The concealed frames fit perfectly into the floor, wall and ceiling. Although the glass elements can reach a maximum of 15 square meters and a weight of up to 1,000 kilograms, intelligent technology ensures they are effortless to move. The different system types, I, II and III, make cero perfect for different requirements.

Great design freedom

cero offers every possibility required from architecturally demanding buildings from a constructive and creative point of view. Light, material, space and nature speak for themselves and the borders between interior and exterior melt away.

Perfect frames

Narrow frames and sections support the maximum transparency of the elements. A mere 34 mm of profile width visible when horizontal and vertical base profiles are sunken into the fabric of the building, which gives a symmetrical and minimalist design, emphasized by 98% glass.

Excellent security

Extremely large glass panels of up to 15 m² put quality and security aspects in special focus. cero is tested and can be certified to the highest security standards (RC2 and RC3). A 2–point rod locking system with adjustable locking points and a hub of 24 mm in the upper running and guide rails is standard. It is also possible to fit connections for alarm installations, or reporting systems such as glass-break sensors or position monitors.

TECHNICAL DATA

Characteristics

Sliding elements (max. width x height)

Fixed elements (max. width x height)

Insulating glass

Daylight / Proportion of glass

Sliding technology

Slide rail / Floor section

Panel weight

Visible width

Frame height

cero I

3 m x 4 m

3 m x 4 m

30-36 mm (Double-glazed)

98%

Carriages and slide rails of stainless steel

barrier-free (in accordance with DIN 18040)

max. 600 kg

circumferential 34mm

0-75 mm

Characteristics

Sliding elements (max. width x height)

Fixed elements (max. width x height)

Insulating glass

Daylight / Proportion of glass

Sliding technology

Slide rail / Floor section

Panel weight

Visible width

Frame height

Thermal separation

Thermal insulation value (glass Ug = 1.1)

Heavy rain impermeability up to class

Air permeability up to class

Resistance to wind load up to

Motorization

Fly protection

cero II

3 m x 4 m

3 m x 4 m

30-36 mm (Double-glazed)

98%

Carriages and slide rails of stainless steel

barrier-free (in accordance with DIN 18040)

max. 600 kg

circumferential 34mm

0-75 mm

In the frame and panel profile

Uw up to 1.35 W/m2K

9A (EN 1027 / EN 12208)

4 (EN 1026 / EN 12207)

B4 (EN 12210 / EN 1627)

Electromechanical drive, automatic operation optional

up to 3.5m high

Characteristics

Sliding elements (max. width x height)

Fixed elements (max. width x height)

Insulating glass

Daylight / Proportion of glass

Sliding technology

Slide rail / Floor section

Panel weight

Visible width

Frame height

Thermal separation

Thermal insulation value (glass Ug = 0.5)

Heavy rain impermeability up to class

Air permeability up to class

Resistance to wind load up to

Motorization

Fly protection

cero III

4 m x 6 m

4 m x 6 m

48-54 mm (Triple-glazed)

98%

Carriages and slide rails of stainless steel

barrier-free (in accordance with DIN 18040)

max. 1,000 kg

circumferential 34mm

0-79 mm

In the frame and panel profile

Uw up to 0.76 W/m2K

E750 (EN 1027 / EN 12208)

4 (EN 1026 / EN 12207)

B3 (EN 12210 / EN 1627)

Electromechanical drive, automatic operation optional

up to 3.5m high

FEATURES

Easy gliding

Stainless steel carriages and rails guarantee easy and low-wear sliding and the integrated stainless steel roller units ensure an even load distribution. An electric panel operation can be installed on request. cero has successfully passed a longevity performance test of 100,000 opening and closing operations.

Intelligent drainage

Draining takes place in a hidden and controlled manner at the lowest level of the frame section. The glass rebate ventilation avoids condensation in the space between the panes.

Handles

– standard grip rails extend to the full height of the panels. Grip profile: 34 mm.

– cero comes with a high-quality, brushed V4A stainless steel handle as standard to guarantee maximum protection against corrosion.

Colour

You can order your cero profiles in any colour you want – you can even choose different colours for indoors and outdoors!

DOWNLOADS

![]() File Name Goes Here

File Name Goes Here![]() File Name Goes Here

File Name Goes Here![]() File Name Goes Here

File Name Goes Here

![]() File Name Goes Here

File Name Goes Here![]() File Name Goes Here

File Name Goes Here![]() File Name Goes Here

File Name Goes Here

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.