Solarlux SL60

Solarlux SL60

The SL60 offers a huge range of installation options. It is available as floor-mounted folding façade, and can be designed to fold outward, inward, to the left or to the right. SL60 can be used as upright units in glass canopies or as pool glazing as well. High-quality fittings are used to achieve large panel weights, while maintaining slim frame sections.

TECHNICAL DATA

Characteristics

Profile system

Panel sizes (max. width x height)

Construction depth

Construction height

Folding inner frame depth

Folding inner frame height

Glazing

Resistance to wind load

Impermeability to driving rain

Air permeability

Sound insulation value

Long-term functional performance

Solarlux SL60

Non-insulated aluminium profile system

1 m x 3 m

(special sizes available on request)

59 mm

50, or 65 mm

59 mm

60 mm

5 – 40 mm

B4 (DIN EN 12211 / 12210)

E1050 (DIN EN 1027 / 12208)

4 (DIN EN 1026 / 12207)

Up to 45 dB (DIN 52210)

3 (DIN EN 1191 / 12400) (20,000 operations)

FEATURES

Safe Operation

The swing panel is locked by means of a special catch ensuring the door can be carried along safely.

Security

Espagnolettes with 24 mm throw lock the panels into the top and bottom track of the frame ensuring they withstand gales and afford high security.

Engineered

Long-lasting stainless steel runners and tracks ensure easy, quiet and smooth operation of the folding glass doors.

Cleaning

The exterior of top hung folding glass doors can be easily cleaned by simply removing the hinge pins.

Height Adjustment

Even after installation the folding glass door can be easily height-adjusted by about 6 mm – which is important if settling of the building occurs.

Width Adjustment

The width of the panels can be altered easily by adjusting the hinges with a screwdriver.

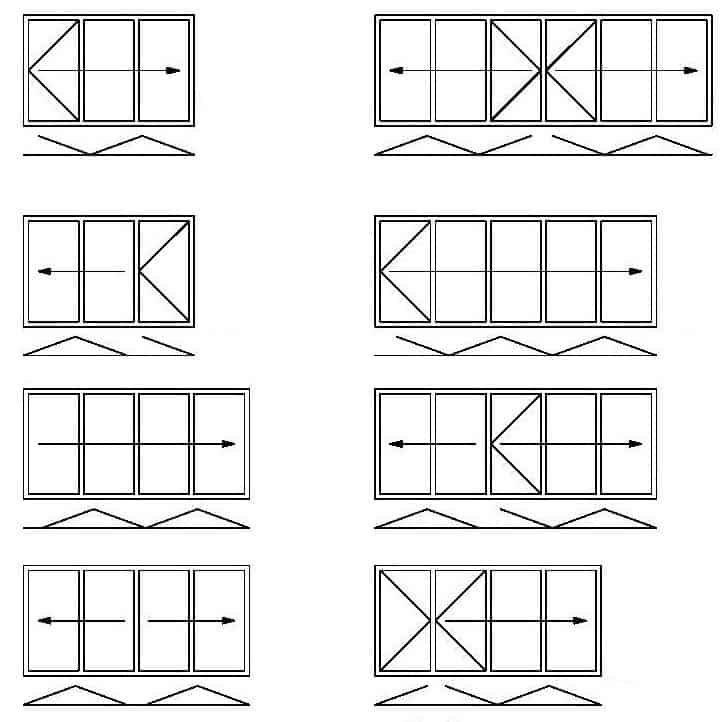

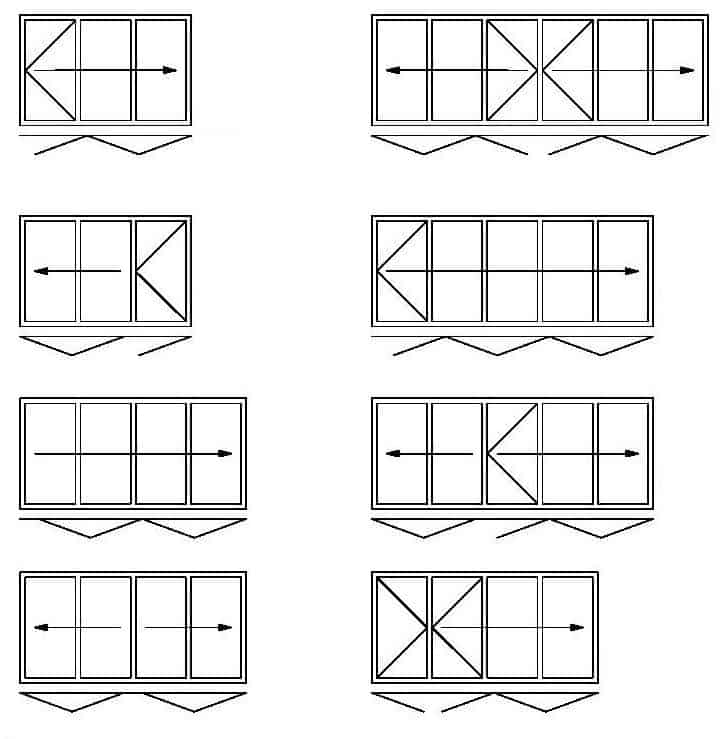

CONFIGURATIONS

Outward Opening (View from Inside)

Inward Opening (View from Inside)

DOWNLOADS

![]() File Name Goes Here

File Name Goes Here![]() File Name Goes Here

File Name Goes Here![]() File Name Goes Here

File Name Goes Here

![]() File Name Goes Here

File Name Goes Here![]() File Name Goes Here

File Name Goes Here![]() File Name Goes Here

File Name Goes Here

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.