Technal SAFETYLINE Louvre System

Technal SAFETYLINE Louvre System

The SAFETYLINE system is ideal for new build or renovation projects involving commercial or residential properties. This louvre system reduces reliance on air-conditioning by favouring the natural ventilation and solar protection of buildings, thus contributing to energy savings.

TECHNICAL DATA

| Characteristics | SafetyLine Louvre |

| Profile System | Aluminium frames with glass or aluminium louvres |

| Max. width per unit | up to 1.4 m (for both manual and motorized) |

| Max. louvre opening angle | up to 80° |

| Max. size for motorization | One motor can run up to 18 aluminium louvres (2.4m high) or 12 glass louvres (1.6m high) |

| Glazing | 5 – 6.6mm |

| Locking mechanisms |

|

| Pull-out resistance of the louvre | Traction in excess of 200 daN |

| Forced entry resistance | Tested and passed |

| Shock resistance | 900 joules (balustrade standards) |

| Hurricane resistance | Class 5 |

| Solar Ageing | No notable change in characteristics after 300 hours |

| Air permeability up to class | 2 (EN-1026) |

| Water tightness up to class | 7B (EN-1027) |

| Wind pressure resistance up to class | C5 (EN-12211) |

| Motorization endurance (internal tests) | Still operational after 30,000 cycles |

FEATURES

A modern window with multiples benefits

SAFETYLINE window offers quality, innovation and design, which are Technal’s strengths.

- Large dimensions

- High level of performances

- Multiple choices of composition: fixed louvres/moving, aluminium/glass/mixed

- Integration of mosquito screen

- Concealed motorization option available and compatible with home automation systems

- Compatibility with TOPAZE range

Comfort and well-being

This solution designed for Jalousie SAFETYLINE motorization reconciles users comfort, access and aesthetics, these are essential brand values. For universal use, Technal’s motorization devices have been shaped to offer self-adjustment for a power voltage between 110 and 240V. Technal also offers an electronic card which functions at high humidity. Thus motorization can be applied in any country, what-ever the climate.

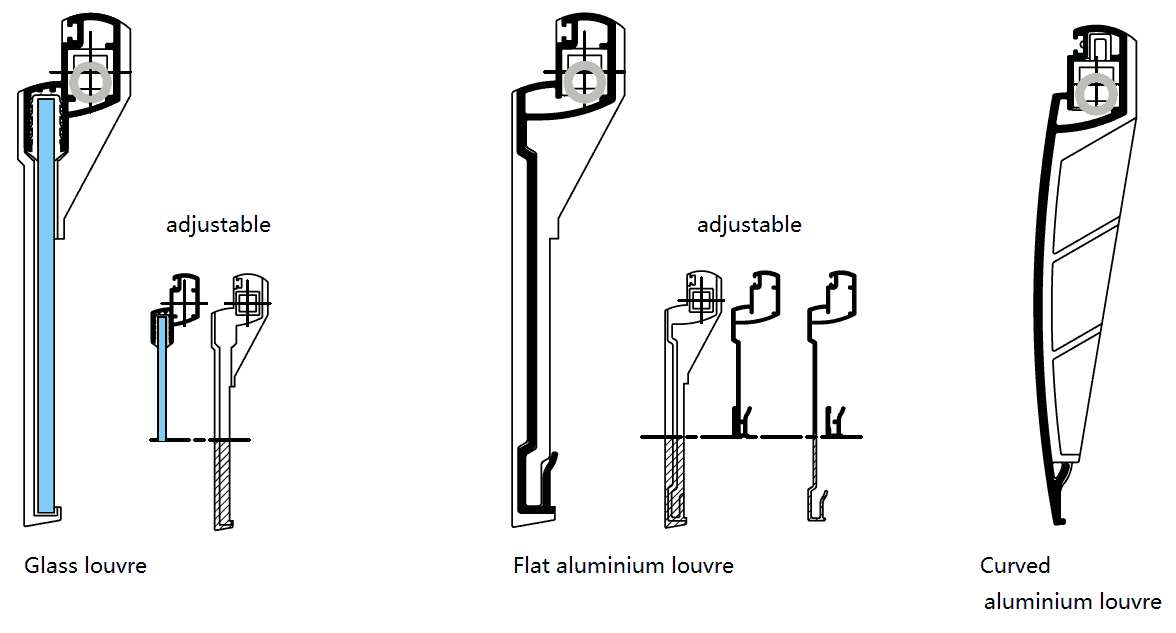

Louvre blade options

Glass or aluminium louvre blade available:

– glass blade with chamfered edges

– flat aluminium louvre blade

– curved aluminium louvre blade

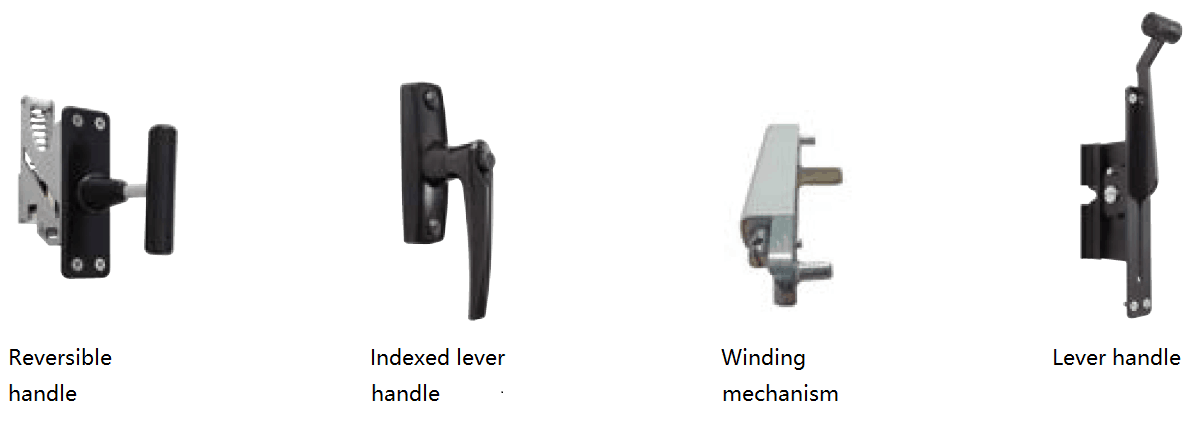

Handle options

Technal developed a complete offer of exclusive-design aluminium handles that provides ergonomics, quality and identity.

APPLICATIONS

DOWNLOADS

![]() File Name Goes Here

File Name Goes Here![]() File Name Goes Here

File Name Goes Here![]() File Name Goes Here

File Name Goes Here

![]() File Name Goes Here

File Name Goes Here![]() File Name Goes Here

File Name Goes Here![]() File Name Goes Here

File Name Goes Here

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.