Technal TOPAZE FB Casement System

Technal TOPAZE FB Casement System

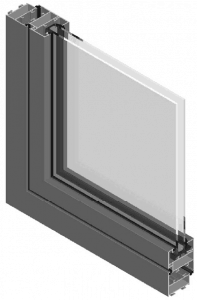

The TOPAZE FB casement frame is fully integrated within the TOPAZE series with no thermal break. Its wide choice of applications and technical solutions makes it ideal for all types of residential and non-residential projects. The TOPAZE FB casement is fully compatible with the door and sliding systems in the suite. It is available in a variety of applications such as single and double sash windows and patio doors with inward or outward opening.

Constructed on a 46mm module, the TOPAZE FB casement meets European standards for acoustic and weather performance. Due to the depth of its offer and its economic solutions, TOPAZE provides the best answer for an optimized design. The TOPAZE FB casement is the ideal system for exterior joinery in hot climates and can also be used for internal partitioning of office areas.

TECHNICAL DATA

| Characteristics | TOPAZE FB Casement |

| Profile System | Aluminium profiles without thermal-break |

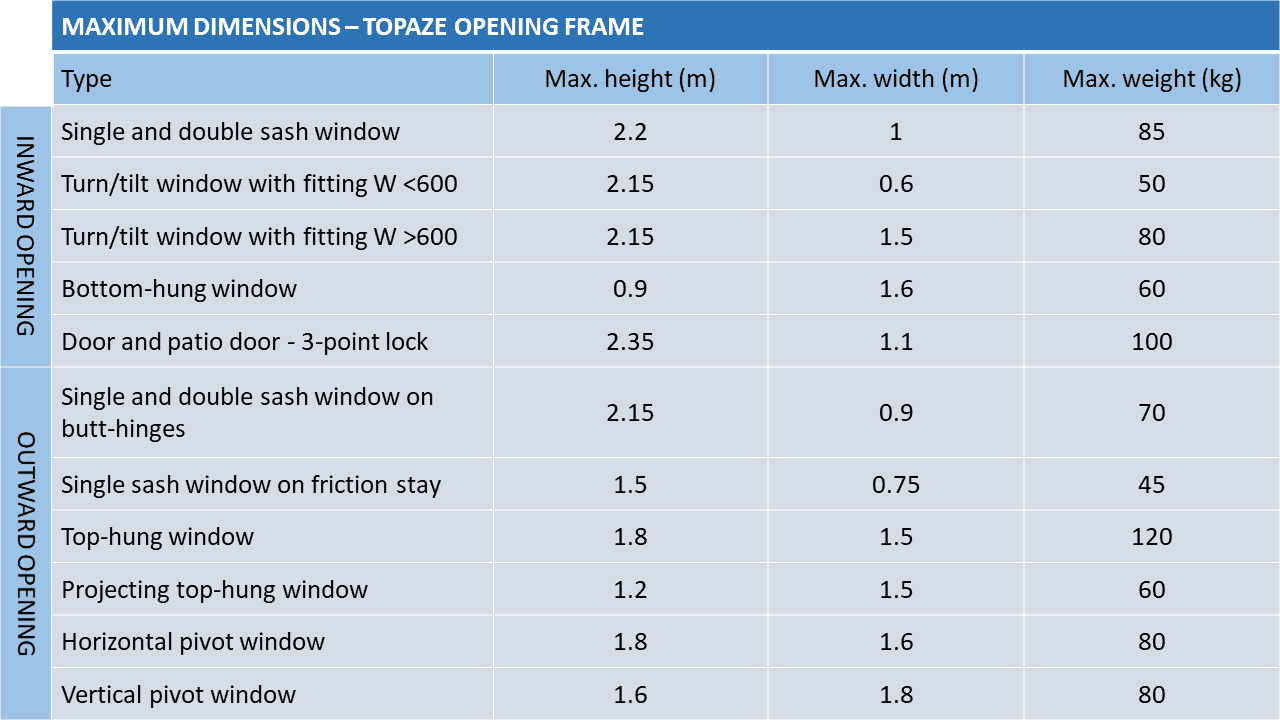

| Max. panel sizes and weight | Please refer to the size chart below |

| Glazing | 6 – 33mm |

| Locking mechanisms |

|

| Option of sash support | Adjustable hinges or friction stay |

| Air permeability up to class | 4 (EN-1026 / EN-12207) |

| Water tightness up to class | 1200A (EN-1027 / EN-12208) |

| Wind pressure resistance up to class | C5 (EN-12210 / EN-12211) |

| Sound insulation up to | 38 dB (Ra, Tr) (EN ISO 140 / EN ISO 717) |

FEATURES

Aesthetic design

- A flat face design for all types of doors and windows, in harmony with architectural trends

- Handle form: an exclusive TECHNAL® design

- Embedded gear box allowing the use of square drive handles for all applications for a discrete appearance

- Exclusive TECHNAL® finishes on profiles and accessories

- Glass surface area: less visible aluminium for more natural light

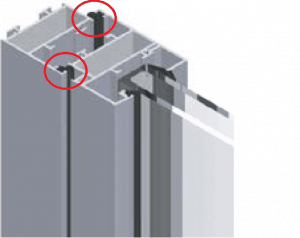

Weathertightness principle

- Double sealing between fixed frame and opening sash by interior/exterior multi-purpose gasket with rounded corners

- The high compressibility of the gaskets absorbs any minor production or installation tolerances and guarantees optimum sealing

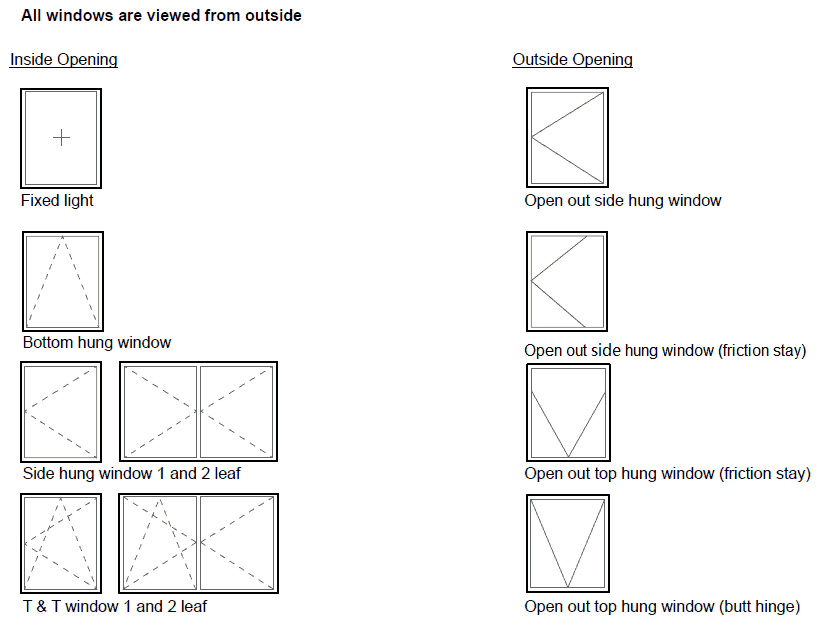

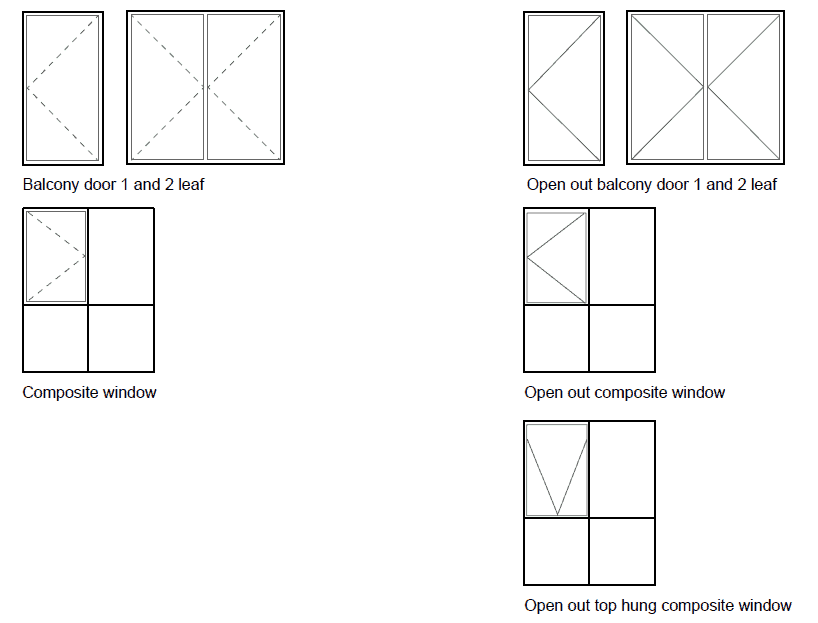

CONFIGURATIONS

MAXIMUM PANEL SIZES AND WEIGHT

DOWNLOADS

![]() File Name Goes Here

File Name Goes Here![]() File Name Goes Here

File Name Goes Here![]() File Name Goes Here

File Name Goes Here

![]() File Name Goes Here

File Name Goes Here![]() File Name Goes Here

File Name Goes Here![]() File Name Goes Here

File Name Goes Here

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.