Technal TOPAZE GB Sliding System

Technal TOPAZE GB Sliding System

Technal TOPAZE (Original, made in France) aluminium section profiles are used to build large size doors with height up to 3.4 meters.

This system has been designed to offer maximum natural light with narrow sight lines. Special reinforced sections improve the profile inertia. With its robust frames, durable hardware, quality tracks, and strong locking systems, Technal sliding system ensures low maintenance, superior reliability and a smooth sliding operation.

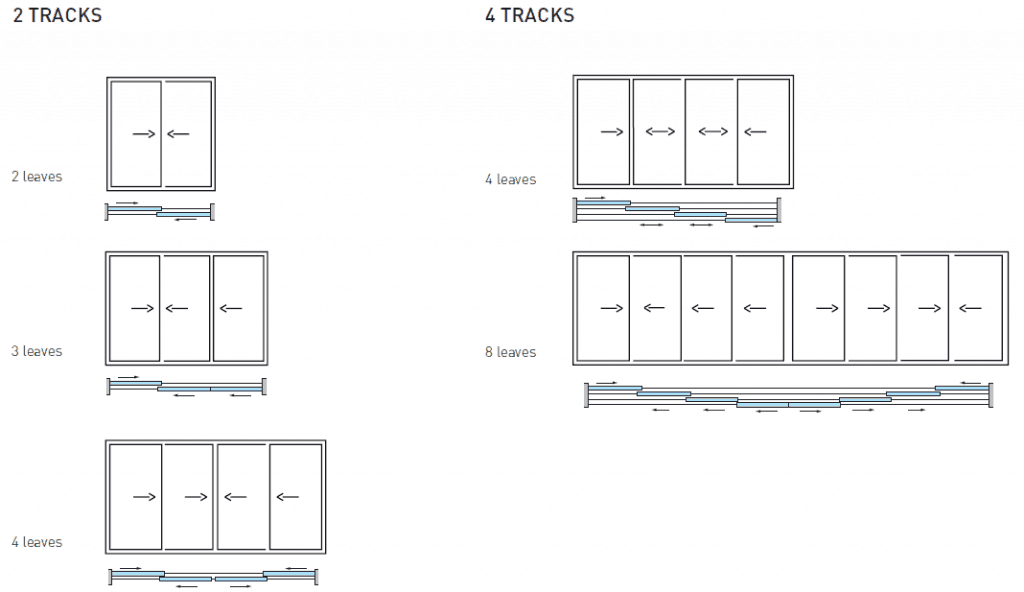

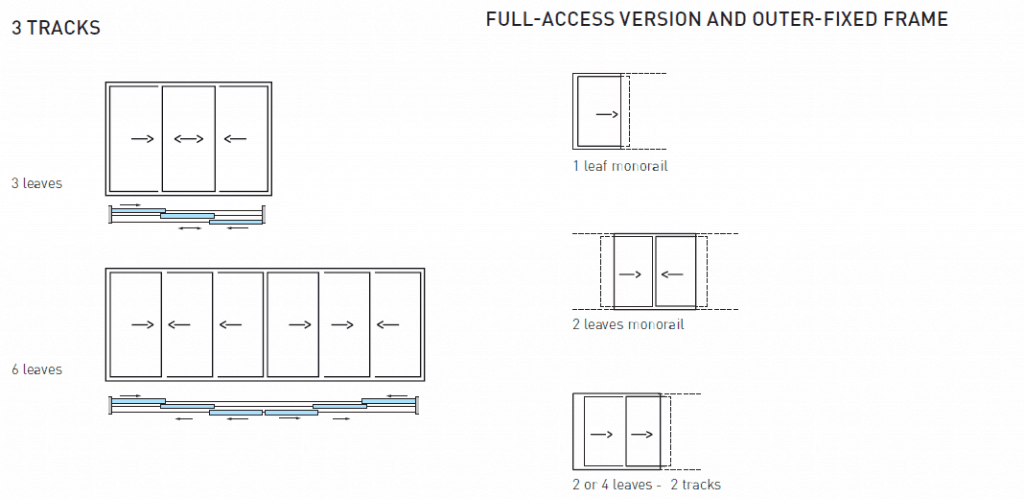

The profiles allow building external doors, with one, two, three, four and more wings.

TECHNICAL DATA

| Characteristics | TOPAZE GB Sliding |

| Profile System | Without thermal break, rounded design |

| Max. height per panel | Up to 3.4 m |

| Max. weight per panel | Up to 200kg |

| Glazing | 6 – 31 mm |

| Locking mechanisms | Up to 4-point closure systems with recessed handles |

| Air permeability up to class | 3 (EN-1026 / EN-12207) |

| Water tightness up to class | 7A (EN-1027 / EN-12208) |

| Wind pressure resistance up to class | C3 (EN-12210 / EN-12211) |

| Sound insulation up to | 33 dB (Ra, Tr) (EN ISO 140 / EN ISO 717) |

FEATURES

Exceptional joinery

- Subjected to 20000 cycles of opening and closing tests, this sliding system guarantees longevity and ease of use with leaves weighing up to 200 kg.

- Available in the traditional version, full-access version and outer-fixed frame application, the use of 6 mm to 31 mm glazing makes it possible to add acoustic, insulation and reinforced security solutions.

Attention to detail

- Locking mechanisms: simple 1-point recessed handle, up to 4-point closure systems with handles and locks.

- Recessed track (stainless steel, aluminium) for greater durability.

- Concealed fixings including matching end caps, plugs and seals for high quality finish.

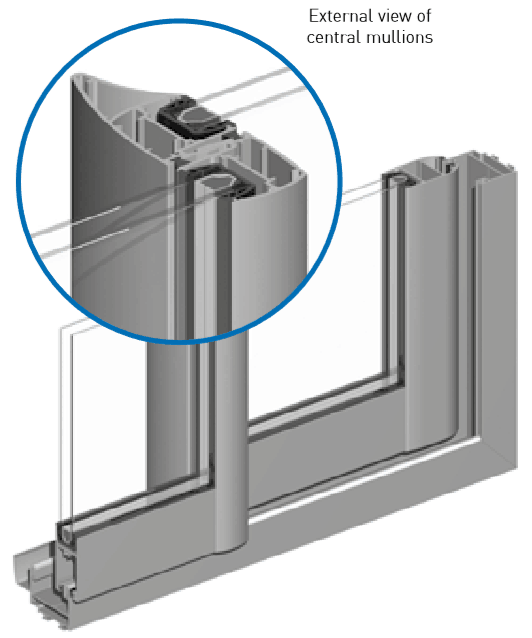

Rounded design

- Central mullion 41 mm, narrow front edge, strong profile.

- Curved lateral mullion.

- Reinforced central and lateral mullions for large scale designs, whereby the mullions can serve as full-height handle, which facilitate operation of sliding doors.

APPLICATIONS

DOWNLOADS

![]() File Name Goes Here

File Name Goes Here![]() File Name Goes Here

File Name Goes Here![]() File Name Goes Here

File Name Goes Here

![]() File Name Goes Here

File Name Goes Here![]() File Name Goes Here

File Name Goes Here![]() File Name Goes Here

File Name Goes Here

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.