Solarlux SL25XXL

Solarlux SL25XXL

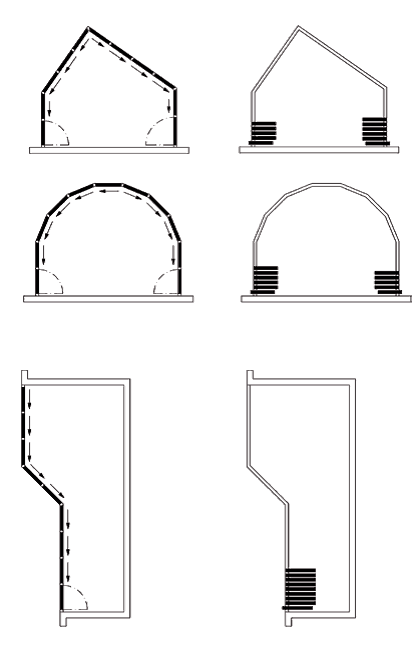

The SL25XXL all-glass slide-and-turn system is ideal for use as balcony glazing. Even in high exposed locations, nothing stands in the way of glazing with this system. It can be slid outwards, inwards, left and/or right as required. Toughened safety glass from 8 mm to 15 mm glass thickness ensures optimum safety even in high buildings.

TECHNICAL DATA

Characteristics

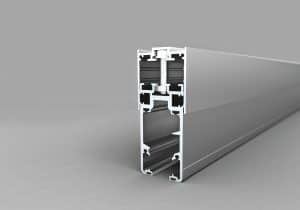

Profile system

Panel sizes (max. width x height)

Profile thickness

Glazing

Max weight per panel

Sound insulation value

Solarlux SL25XXL

Top and bottom aluminium profiles, no vertical frames

0.8 m x 2.75 m

(special sizes available on request)

31 mm

8 – 15 mm

65 kg

Up to 26 dB (DIN52 210-3)

FEATURES

Engineered

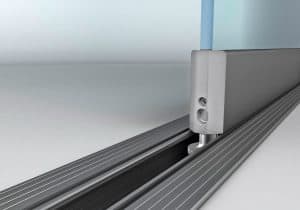

Carriers with twin ball bearing runners and 65 kg load bearing, guarantee that the glass panels slide extremely smoothly.

Barrier Free

The flush floor track ensures barrier free living for both patio or balcony.

Transparency

The SL 25XXL frameless system is completely transparent whilst providing protection from rain and reducing noise.

Safety

The single pane safety glass, which can accommodate glazing thicknesses between 8 – 15 mm, provides ample for high buildings.

Opening

The release cable and knob provide easy internal and external one hand operation.

Ventilation

The lockable two-step ventilation allows controlled air circulation (optional).

Height Adjustment

The height compensation profile allows adjustment of up to 35 mm for the panels even after installation.

Security

As an alternative to the cable release a brushed stainless steel door handle can be fitted for added security (optional).

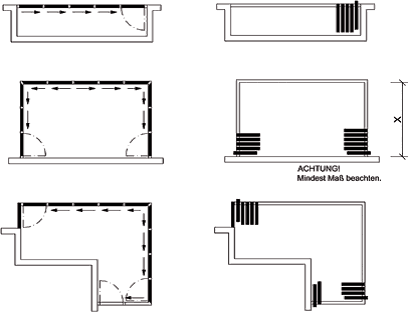

CONFIGURATIONS

Closing and Opening Position (View from Inside)

DOWNLOADS

![]() File Name Goes Here

File Name Goes Here![]() File Name Goes Here

File Name Goes Here![]() File Name Goes Here

File Name Goes Here

![]() File Name Goes Here

File Name Goes Here![]() File Name Goes Here

File Name Goes Here![]() File Name Goes Here

File Name Goes Here

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.