Technal TITANE Door System

Technal TITANE Door System

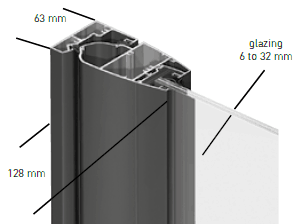

Designed from a 63 mm module, the TITANE door features a particularly robust hinge system: on the lower section there is a self-lubricating ball joint fixed to a hinge bearing and on the upper section there is an adjustable unit with a stainless steel arm.

The TITANE door has been carefully styled and features elliptical profiles, the concealed closing systems and hinges, and the fact that the door closer is recessed into the transom of the opening frame. Security is reinforced with the integration of essential features such as security bolts, the integrated door-closer, the 3-point pivoting deadbolts and the electromagnetic closure systems with 600 kg retention capacity (2 suction cups) which are recessed into the transom of the opening frame. This door has been approved for use in French social housing

With its proven endurance, having undergone 1 million test cycles, and large dimensions (2.5 m high and 1.3 m wide per leaf), the TITANE door is ideal for use at the entrance to apartment blocks, public buildings, schools, offices, etc.

TECHNICAL DATA

| Characteristics | TITANE Door |

| Profile System | Aluminium profile without thermal-break |

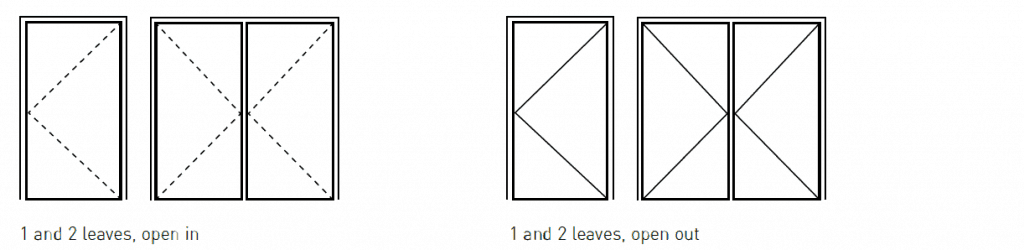

| Panel sizes (max. width x height) | Up to W 1.30m x H 2.50m |

| Max. weight per panel | Up to 140 kg |

| Glazing | 6 – 32mm |

| Locking mechanisms |

|

| Torsion and buckling tests |

|

| Endurance testing | Subject to more than 1,000,000 opening/ closing test cycles (EN 1191): class 8 on the EN 642-E scale |

| Forced entry delay | Level 2 (EN 1627) for door fitting with 2 shear locks and a 3-point lock with rollers |

FEATURES

Design

- Rounded shape identical to the profiles of the opening/outer frames and the fixed sections on the composite frames.

- Minimal aluminium thickness (128 mm).

- Continuous intermediary transoms between opening frames and fixed sections.

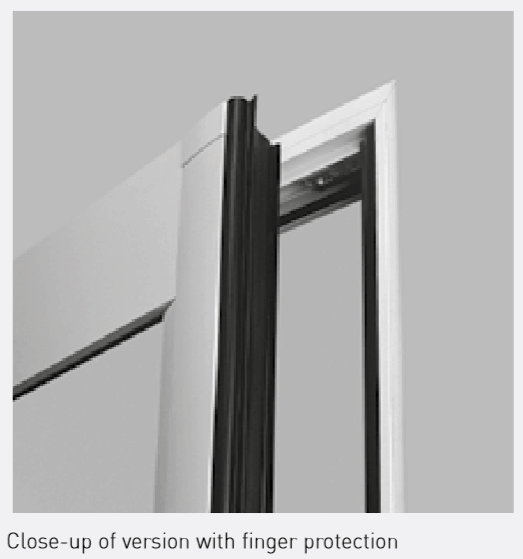

- Available version with finger protection.

- Patented system: concealed top and bottom hinges.

Bottom Section:

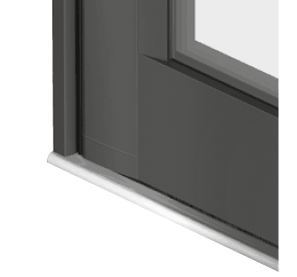

Centre plate assembly set into the ground and a corner piece forming part of the opening frame fitted with self-lubricating needle roller bearing.

Top Section:

Casing with adjustable rod fixed to the outer frame with an insert.

Reinforced security

- Level 2 classified door according to the standard EN1627.

- Concealed hinges.

- Door-closer is recessed into the transom of the opening frame.

- Inaccessible external glazing gaskets.

- External glazing stops are clipped and screwed into the recess.

- Fixed internal glazing stops for forced entry and vandalism delay.

Locking mechanisms

- Option of electromagnetic lock recessed into the mullions for an extraction resistance of: 300 kg/standard electromagnetic lock, 750 kg/shear lock.

- Technal locks:

– 1-, 2- or 3-point with rollers, recessed or on a full-length face plate

– 3-point pivoting deadbolt

– Emergency access cremone bolt

– Electric strike

– Push button

Handle options

Several exclusive design handles are available as shown below.

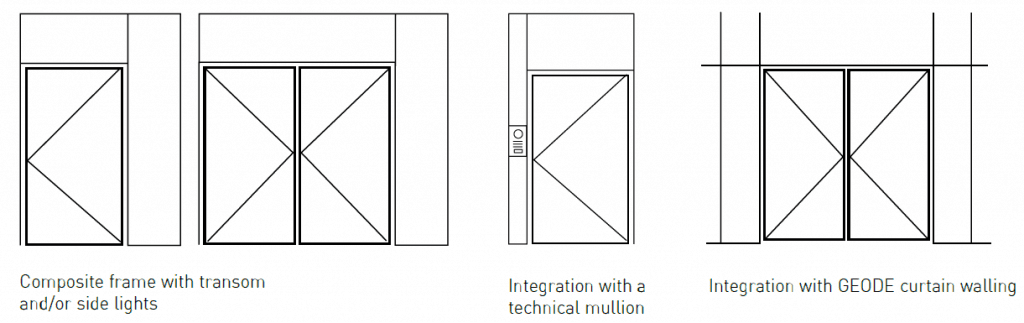

APPLICATIONS

DOWNLOADS

![]() File Name Goes Here

File Name Goes Here![]() File Name Goes Here

File Name Goes Here![]() File Name Goes Here

File Name Goes Here

![]() File Name Goes Here

File Name Goes Here![]() File Name Goes Here

File Name Goes Here![]() File Name Goes Here

File Name Goes Here

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.